RAG – Renewables and Gas

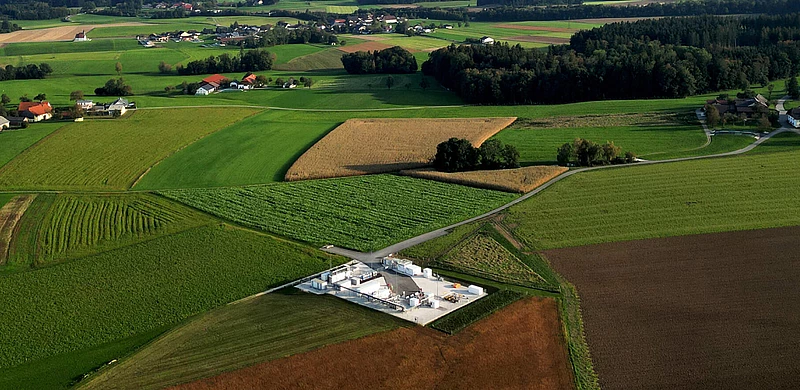

RAG Austria AG is Austria’s largest energy storage company, and one of Europe’s leading gas storage facility operators.

Our business focus is market driven storage, conversion and conditioning of energy in gaseous forms.

We also develop leading edge energy technologies related to green gas like hydrogen that partner renewables.

©

©

„H2 cross border“ - hydrogen delivery from Austria to Germany still faces hurdles - Germany lacks a register of origin

The “H2 cross border” hydrogen project successfully maps the entire hydrogen value chain, from production and storage to transport and delivery to the end consumer. It shows that the cross-border pipeline transport of green hydrogen from Austria to Germany is possible under the existing technical and regulatory framework. At the same time, it is clear that the market ramp-up continues to be slowed down by a lack of regulatory requirements, in particular the lack of a register of origin in Germany.

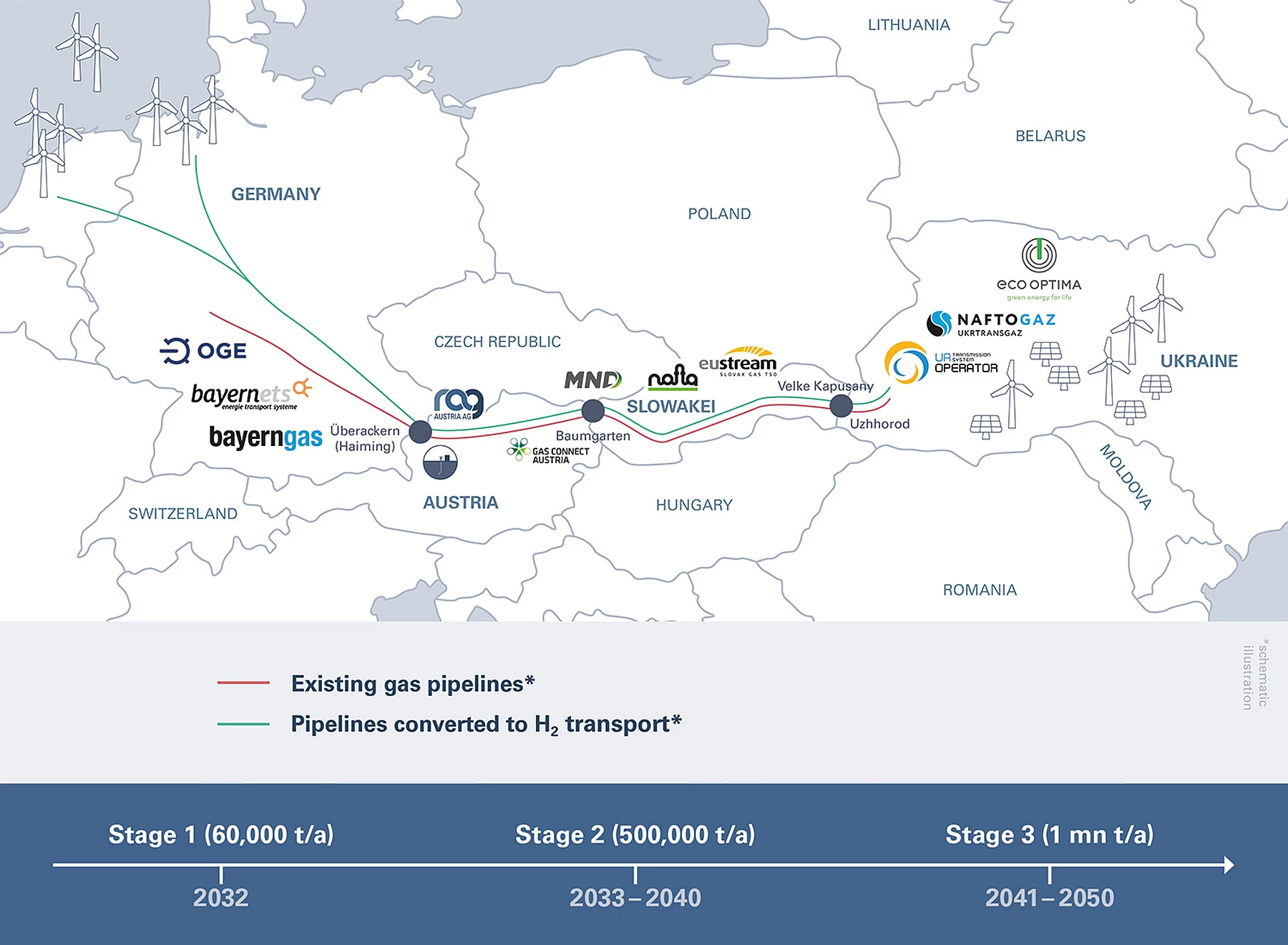

H2EU+Store: Feasibility study confirms great potential for green hydrogen from western Ukraine

The international industry partnership H2EU+Store has completed its feasibility study. The study examined all key areas of the entire hydrogen value chain – from production and transport to potential consumption (upstream, midstream and customer demand).

The results show that green, RFNBO (Renewable Fuels of Non-Biological Origin) compliant hydrogen can be produced on a large scale at competitive prices in western Ukraine and transported to Central Europe via existing infrastructure.

©

©

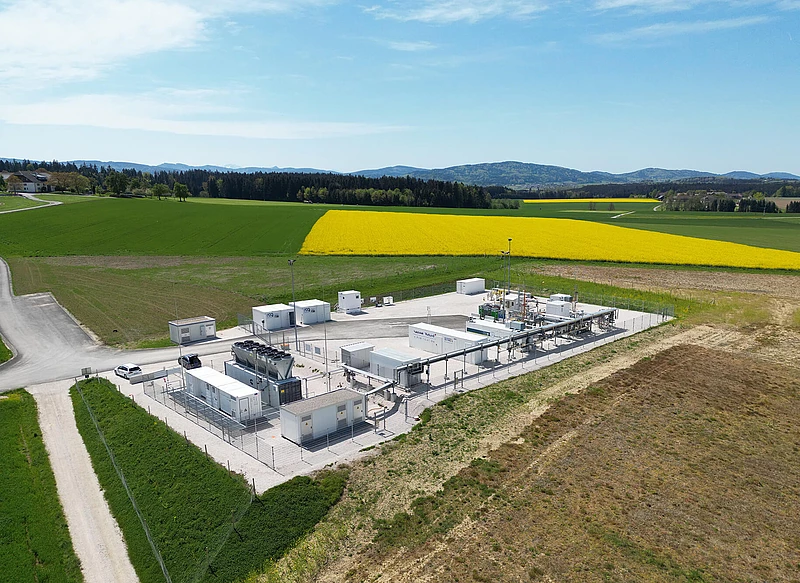

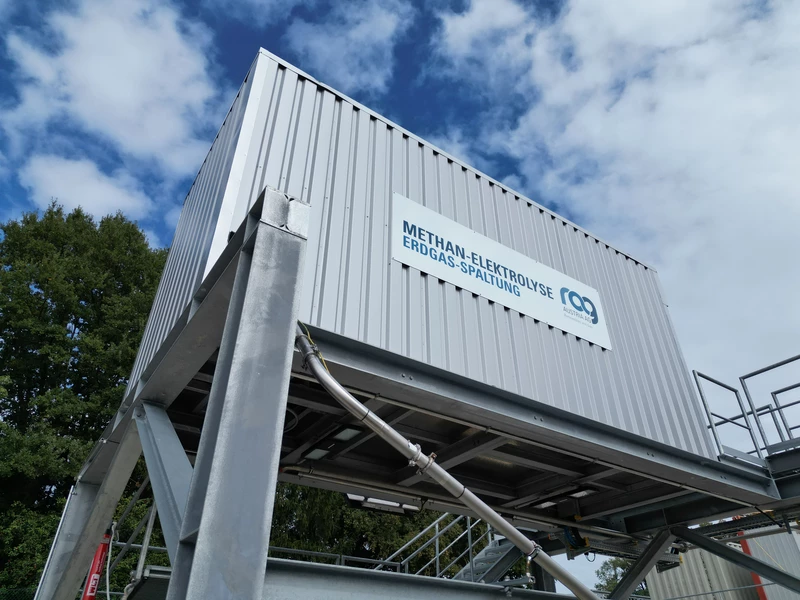

"H2Austria&Bavaria+Store electrolyser" project receives PCI status from the European Commission

Hydrogen is a key component in achieving climate targets and enhancing security of supply in Europe. In this context, on December 1, 2025, the European Commission recognized the project “H2Austria&Bavaria+Store electrolyser”, initiated by RAG Austria AG and part of the Hydrogen Interconnections in Western Europe (HI West) network, as a Project of Common Interest (PCI). Thereby its strategic importance for Europe is confirmed. With PCI status, RAG's project can benefit from accelerated approval and implementation processes.

©

©

New BMWET study confirms: Austria needs large-scale hydrogen storage

On 22 November 2025, the study “Hydrogen Storage in Austria”, commissioned by the Federal Ministry for Economy, Energy and Tourism, was presented. The study makes clear: The energy transition will not succeed without large-scale seasonal storage. RAG Austria has already successfully implemented the required technology at the Upper Austrian Molasse Zone.

Key Findings:

- Hydrogen demand will increase from 5 TWh (2030) to 48 TWh (2040)

- Storage demand will grow from 1.2 TWh to 7.7 TWh over the same period

- Storage facilities make a crucial contribution to security of supply, especially in the event of import disruptions or periods of low renewable generation

Only with sufficient storage capacity Austria can reliably supply itself with electricity and heat from dispatchable power plants, rather than merely producing green electricity on a balance-sheet basis over the course of a year.

RAG Austria has already successfully implemented the required technology: the international flagship project Underground Sun Storage has proven that green hydrogen can be stored safely, efficiently, and seasonally in former natural gas storage facilities. This expertise is now being incorporated into the European reference project EUH2STARS, which aims to further scale up hydrogen storage.

APA-OTS | 22 November 2025

“We have been shaping the energy world for nine decades, successfully ensuring security of supply, driving innovation and pointing out new paths and prospects for the future.”

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/1/csm_RAG-Speicher-Puchkirchen_b6ea20c630.webp)